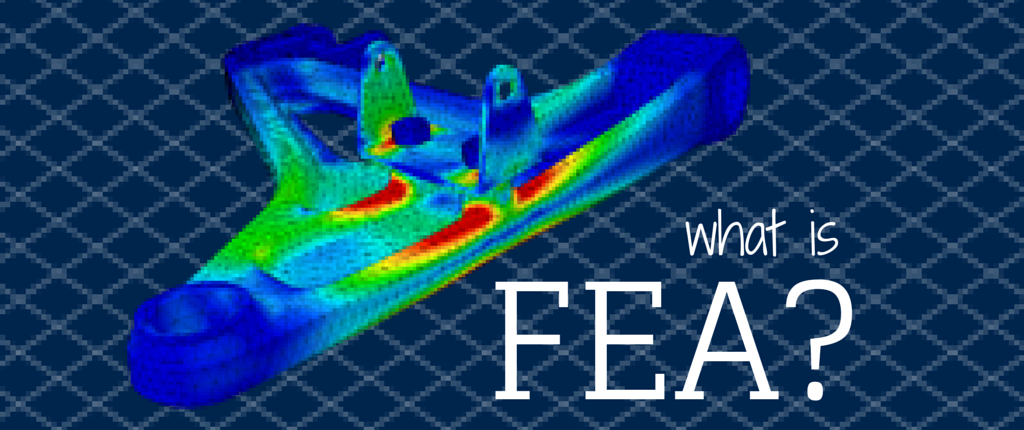

FINITE ELEMENT ANALYSIS (FEA)

1. Definition of FEA

Finite element analysis (FEA) is the use of calculations, models, and simulations to predict and understand how an object might behave under various physical conditions. The analysis includes bringing the object in contact with force, heat, vibration, fluid flow, and other such physical conditions. The FEA can predict if the product is likely to break, tear, wear, or behave the way it is manufactured to.

2. Benefit of FEA

- Engineers use FEA to identify vulnerabilities in their design prototypes. As a consequence, FEA can help to improve the quality and function and create a new design to meet the necessary conditions.

- Earlier testing in the development process Virtual prototyping allows the designer to model various designs and materials in a matter of hours, rather than the days or weeks it takes to produce hard prototypes.

- increased productivity and revenue because FEA software allows developers to produce higher-quality products in a shorter design cycle while also using less material.

- Enhanced insight into critical design parameters as the result of being able to model both the design's interior and exterior This allows designers to determine how critical factors affect the structure as a whole, as well as why and where failures might occur.

- Finite element analysis (FEA) is the modeling of products and systems in a virtual environment, to find and solve potential (or existing) structural or performance issues.

3. Application of FEA

What are the main applications of finite element analysis (FEA)?

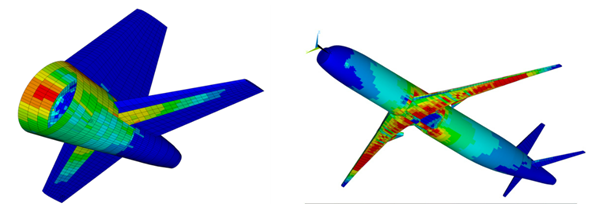

FEA is a method that has a wide range of applications and is important in the design of aircraft, spacecraft, and cars to the design of advanced drill bits at oil rigs.

This numerical calculation method is used in many fields of engineering and research and allows efficient and precise modeling of the behavior of mechanical, thermal, or other complex systems. This method separates a complex geometry into a network of nodes and elements of simpler shape and equations, called a mesh.

-

HARDWARE OF TRAVEL & CAMPING 2024

-

HARDWARE OF BAGS & APPARELS 2024

-

METAL & PLASTIC COMPONENT

-

T3 PRO_METAL COMPONENT